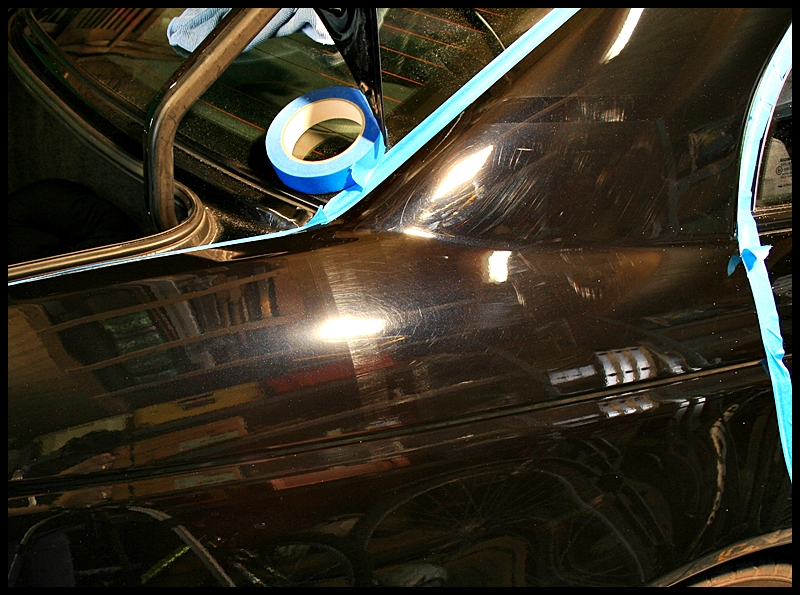

Managed to find a bit of time to start polishing again. The car wasn't very dirty at all so i didn't wash it, instead i just wiped down the panel i was going to work on with ONR and then clayed it. Either my half arsed cleaning attempt or the clay made the marring appear worse, live and learn though, i'll be a bit more careful next time. First time using BH clay too and i probably didn't use enough water which didn't help.

So, the rear o/s quarter was what i worked on this afternoon for a short while, in between running my lad to Toys R Us (needs a water pistol for a water fight at school tomorrow, the same school that has cancelled sports day twice as the ground might be a bit slippery :dunno: ) and picking the missus up from work.

Anyway, under the lights, the scratches and swirls show themselves...

Using my DAS6 with Gtechniq P1 on a Megs polishing pad, i did the half the roof support first to see how things went. Came up very well, not quite the level of correction i wanted, but i think i need a cutting pad to get any better results (my cutting pad has had it's day now, i must get a new one!). Finished off with P1 on a finishing pad -

Next onto the rear panel which needs some work

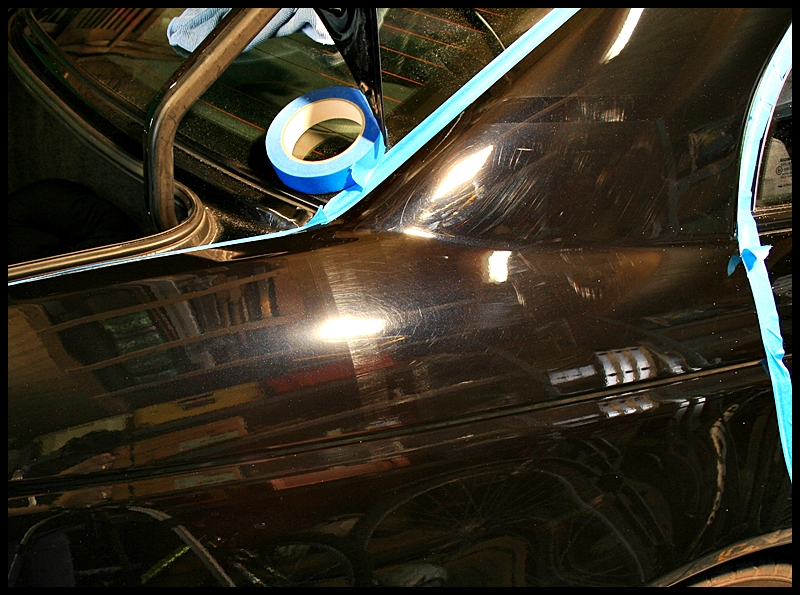

Same method, some 50/50s -

Finished the rest of the panel, glazed with Poorboys Black Hole, sealed with Chemical Guys Blacklight and V7. Closer inspection reveals a few marks still left behind. I really am in two minds as to what to do here, I got the boot near on perfect using Menz polishes, but even with the most careful wash method and the plushest of microfibres, the paint still scratches, it is seems much softer even than my previous two Hondas. I'll have to decide whether to up the cut a bit more to get rid of the remaining scratches or accept that no matter what i do, i'm going to end with marring on it anyway!

Finally a couple more shots. The rear panel looks a different colour to the door in the first picture, but it is only as a result of the light reflecting in a different manner where it is polished and being picked up different by the camera.

Just got to find time to work round the rest of the car now!